24/7 CP monitoring with IoT measurement devices and a cloud-based CP monitoring dashboard

Cathodic protection (CP) is used to protect your pipelines against corrosion. CP systems need to be monitored to avoid malfunctions, the beginning of corrosion, or even worse: a leak on a weak spot of the pipeline.

Our IoT measurement devices, which are installed throughout your pipeline network, monitor the voltage and current of your CP system 24/7 to check whether your pipelines are still fully protected. All the findings detected by the IoT sensors can be managed in our cloud-based CP monitoring software application.

Make strategic decisions based on accurate data, reduce costs and manage risks on your pipeline network with our continuous cathodic protection monitoring IoT sensors and online business application.

Want to know more about the capabilities of continuous cathodic protection monitoring?

Experience the CP monitoring software application during a demo

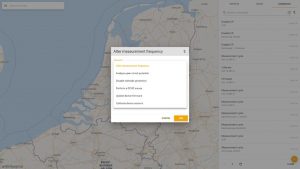

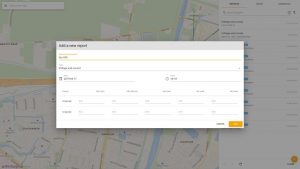

The cloud-based CP monitoring software application of our partner is a highly secure tool and can be accessed by desktop, tablet, and mobile phone. The application gives you an overview of the collected data from the measurements performed by the IoT devices. If required, the application can be synchronized in real-time with your GIS system or with our Pipeline Integrity Management System PRIMS.

Functionalities include:

1. Historical measurements for an overview per measurement location, pipeline network or area

2. Setting thresholds per measurement and alarms

3. Adding manual measurements

4. Issue tracking when a threshold is crossed

5. Sending product-specific commands to the IoT devices

Book your free demo and experience the application yourself.

Benefits of continuous cathodic protection monitoring

Take immediate action when needed

Thresholds per measurement can be set per location, pipeline network or area. In the event of a malfunction above a certain threshold, the appointed person immediately receives a message, followed by issue tracking.

Reduce costs

The IoT sensors are a low-cost investment and they are easy to install. Avoid costs by detecting possible damages and anomalies faster with 24/7 monitoring.

Manage risks

The IoT measurement devices can be used at locations that are difficult to reach or are dangerous so you avoid risks. By monitoring continuously, you receive valuable insight into the quality of your CP system faster.